WATER, MICROBES & SLUDGE

Fuel issues are the #1 cause of equipment failure.

DID YOU KNOW? Over 60% of injector failures are from contamination.

Stored Fuel Doesn’t Tend to be Checked.

When you dig into these “fuel issues”, it becomes apparent that diesel fuel contamination is a primary problem that deserves both blame and consideration

TOP 3 FUEL CONTAMINANTS

#1 Water

Today’s fuels like to hold on to water. The common practice of blending low levels of biodiesel is hygroscopic and migrates toward any water presence in the fuel. Lubricity additives increase fuel surfactancy, which has an unintended effect of increasing the stability of water trapped in fuel.

- Water allowed to accumulate in a tank increases the chance of a microbial infestation

- bacteria and fugi which can play havoc with the fuel system

- Water in the fuel accelerates the oxidation and break down of the fuel

- Water contamination contributes to tank corrosion

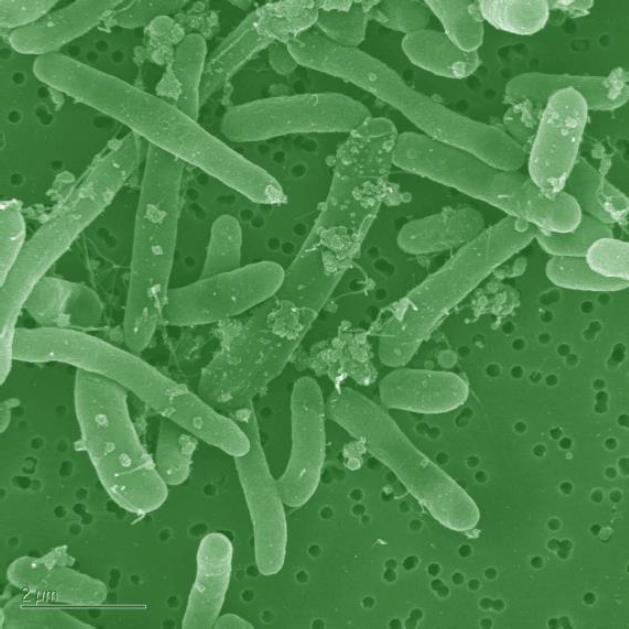

#2 Microbes

Today’s ULSD fuels have virtually no natural resistance to microbial growth because of the removal of the fuel sulfur. Sulfur, historically, has functioned to retard microbial growth — they don’t like to be around it. And it’s not just sulfur, it’s also the mandate reduction in aromatic content of ULSD. Microbes don’t like to consume aromatic hydrocarbons as a fuel source. If you reduce their proportion in the fuel makeup, you increase the amount of the things microbes do not like to feed on.

Fuel Microbe Contaminants Linked to:

Filter Plugging

Microbes grow in the fuel tank, multiply, and produce biomass and slime growths which will plug filters in the storage tank and spread quickly. So, if you’re a fuel or tank manager and you notice an increase in the rate of filter changes needed, that’s one sign you need to look closer at what’s happening in your tank.

Fuel Instability

When the fuel quality is degraded, it increases the chance of system failure and engine shutdown.

Microbe-Related Corrosion in Storage Tanks

Some kinds of bacteria have been known to perforate a 5mm thickness of 316 steel in little more than one month.

#3 Sludge

This is a problem because, first, sludge like this represents energy value that’s not contributing when the fuel is burned. And second, sludge can plug filters and contribute to engine deposits if it happens to be consumed by another piece of equipment that share the same fuel source.

Questions you need to ask yourself:

- Have you checked your tank(s) lately?

- When’s the last time your fuel was tested?

- What can you expect if the fuel is bad?

- Have you checked for microbes?

- Which one is best for you? Mechanical or Chemical solutions?

- Can you do it yourself?